1. PRODUCT AND COMPANY IDENTIFICATION

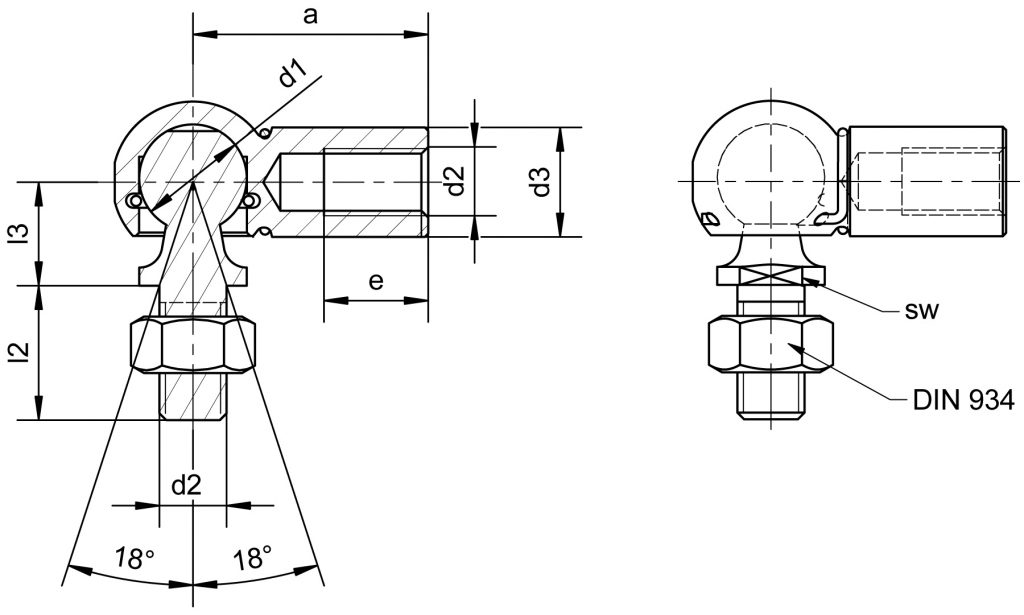

- Product Description: Gas Springs

- Primary use: Motion Control/ Assist

- Manufacturer:Winco Easylift BV

- Zutphenstraat 69c

- 7575 EJ Oldenzaal, The Netherlands

- Emergency Telephone +31-541-520044

- Contact Mr Clemens Janssen

2. PRODUCT CONTENT INFORMATION

- Description: It is a closed system containing tube + piston rod + Seals + oil + nitrogen gas.

Dangerous Components: Void

- Additional Information: Gas Springs contain up to a maximum of 0.25 litres of compressed gas (nitrogen) at a pressure of between 0 and 180 bar.

- Composition / Information on Ingredients

- For Nitrogen Gas Component : Nitrogen (N2), CAS Number : 7727-37-9, Concentration (Volume) : 99,99 %

- For Oil Composition : Solvent refined paraffinic base oils and additives.

| Hazardous components |

EC Hazard Symbol |

EC Risk Phrases |

Concentration |

| Mineral Oil |

N |

R22/52 |

80-90 |

| Additives Methacrylate |

N |

R51/53 |

| Anti-wear, anticorrosion |

N |

R36/37/38 |

3. HAZARDS IDENTIFICATION

The gas spring is filled with compressed nitrogen (colourless, odourless, inert inflammable gas).

Gas springs should not be heated or opened.

Information pertaining to particular dangers for man and environment:

- Caution Pressurised Container.

- Nitrogen is suffocating by replacing ambient oxygen.

- Injection of oil through the skin resulting from contact with oil at high pressure constitutes a major medical emergency.

- Oil is water polluting and some may be harmful to aquatic life.

Hazard Description:

In its manufactured state, and under normal and expected conditions of use, the product is not expected to cause any acute or chronic health effects. The health effects listed below are for accidental release of gas or oil if the product is damaged.

Route of entry:

- Skin contact: Handling of oil causes no particular hazard when appropriate personal protective equipment is used taking normal handling precautions.

- Eye contact: Oil may cause irritation with prolonged contact.

- Skin Absorption: This is not expected to be an entry route in to the body.

- Ingestion: This is not expected to be an entry route in to the body.

- Inhalation: This is not expected to be an entry route in to the body.

4. FIRST AID MEASURES

- Skin Contact: Wash thoroughly with mild soap and water. Seek medical attention if irritation develops. Change clothes or shoes contaminated by the oil and launder thoroughly before reuse. (Never put rags contaminated by the oil into cloth pockets).

- Eye Contact: Immediately flush thoroughly for at least 20 minutes. Seek medical attention if irritation persists.

- Inhalation: Provide fresh air. Keep victim quiet and warm. If breathing is difficult, oxygen may be administered. If breathing has stopped artificial respiration should be started immediately. Seek medical attention.

- Ingestion: This is not expected to be an important route of entry in to the body. If large amounts of oil are ingested, do not induce vomiting. Seek medical attention immediately.

5. FIRE FIGHTING MEASURES.

- Extinguishing Media: Use water fog, foam, dry chemical or carbon dioxide extinguisher or spray.

- Fire Fighting Procedures: As in any fire, self-contained breathing apparatus should be used. Water containing oils should be prevented from being discharged into any waterway, sewer or drain.

- Unusual Hazards: Small quantities of irritating and/ or toxic and/ or asphyxiate gases may be released during a fire. Sources of these gases are in very small quantities in each spring.

- Hazardous Combustion: Oil may produce Carbon monoxide, metal oxides, and elemental oxides. Only a small amount of oil is present in each spring.

- Condition under which ignition occurs Exposure to fire may cause containers to rupture or explode. Non-flammable.

- Additional Information:

Remove items from incendiary zone, if possible. Cool endangered items with water spray.

6. ACCIDENTAL RELEASE MEASURES.

- Person related safety precautions: Ensure adequate ventilation, Keep away from ignition sources, Particular danger of slipping on leaked oil.

- Measures for environmental protection: Do not allow oil to enter drainage system, surface or ground water. Do not allow accumulation of large quantities of gas in basements, work pits/ sewers, or other low lying areas where accumulation could be dangerous.

- Measures for cleaning/ collecting: Absorb oil with liquid binding material (e.g. sand, sawdust, diatomite, universal binders) and dispose in suitable containers.

7. HANDLING AND STORAGE.

HANDLING:

Information for safe handling: Do not dent or pierce the spring, which contains a pressurised gas.Do not heat spring, which contains pressurised gas.

STORAGE

- Store in a cool dry, ventilated area, preferably rod down.

- Do not store gas springs more than one year

- Store away from food stuffs.

- Local regulations concerning handling and storage of water polluting products have to be followed.

8. EXPOSURE CONTROL AND PERSONAL PROTECTION.

- Components with limit values that required monitoring at the workplace:

7727-37-9 Nitrogen, TLV Simple asphyxiate.

- Personal protective equipment:

General protective and hygienic measures: Wear suitable protective clothing at work. Avoid close or long term contact with skin. Do not carry cleaning cloths impregnated with oil in clothing pockets.

- Breathing Equipment :

Not required, local ventilation to ambient air.

- Gloves:

Not required, However good personal hygiene practices should be followed.

- Eye

Normal industrial eye protection practices should be employed.

Other Equipment Not required.

9. PHYSICAL AND CHEMICAL PROPERTIES.

General Information:

The product itself is a metal tube containing an extending piston rod, filled with nitrogen gas and a small amount of oil. The product itself has no noticeable odour.

The information below is for the gas and oil contained in the tube.

Gas spring

- Surface roughness value Ra = max.20μ

- Dye thickness 30μ - 40μ

- Corrosion endurance 250 hours

Oil

- Density at 15єC kg / m3 0,887

- Flash point 140єC

- Viscosity ( 40єC , cSt.) 68

- Pour point -45єC

For Nitrogen Gas

- Form: Compressed gas

- Color: Colorless gas

- Oder: No odor warning properties

- Molecular weight: 28,01g/mol

- Relative vapour density: 0,967 (Air=1)

- Density: 1,170 Kg/m3 (15 єC, 1bar)

- Specific volume: 13,80 ft3/lb (0,8615 m3/kg) at 70 єF (21 єC)

- Boiling point/range: -195,8 єC (-321 єF)

- Critical temperature: -147 єC (-233 єF)

- Melting point/range: -209,86 єC (-346 єF)

- Water solubility: 20 mg/l

10. STABILITY AND REACTIVITY

- Chemical stability: Product is stable if stored and used within normal conditions.

- Conditions to be avoided: Avoid storage above 50�C.

- Do not expose to strong acids or oxidising agents.

- Reactivity: Product is stable.

- Hazardous Decomposition Products: Product is stable.

11: TOXICOLOGICAL INFORMATION

When used and handled according to specifications this product does not have any harmful effects.

- Nitrogen Gas: No known toxicological effects.

- Suffocating Symptoms: Fast and hard breathing, fast tire, nausea/vomit and death after loss of conscious.

High concentrations of Nitrogen gas act as an asphyxiant.

Oil

Acute toxicity: Not applicable

Primary irritant effect:

- On Skin: No known irritant effect

- On Eye: No known irritant effect

- Sensitisation: No sensitising effect known.

- Additional Information: The manufacturer does not indicate that any of the oil constituents are highly toxic at concentrations present in the product.

12: ECOLOGICAL INFORMATION

Nitrogen Gas

Nitrogen is made of by compressing and decomposing the air. It has no harmful effect on ecologic

balance.

Oil

Do not allow to reach ground water, water bodies or sewage systems. Oil is harmful to aquatic

organisms. The oil swims on water surface.

13. DISPOSAL CONSIDERATIONS

Prior to disposal of product, gas pressure should be relieved to atmosphere in a well-ventilated place,

and hydraulic fluid drained by a qualified mechanic.

Recycling of product is the recommended method of disposal.

All wastes should be evaluated with regard to local regulations and disposed of accordingly.

It is the user�s responsibility to dispose of all wastes in accordance with local, state and federal

regulations, at properly permitted or authorised facilities.

14. TRANSPORT INFORMATION.

- HS-Code Harmonized System code - 870 880 20

- UN ID No.UN3164

- Class 2,2

- Label 2,2

- Designation: Articles Pressurized pneumatic or Hydraulic containing non-flammable gas

- Packing group ADR IMDG IATA: Void

- Road Carriage � RID

- Danger code 6A

- Special provision 283 371 594

Exempt from ADR regulations as special provisioned

- Sea Carriage - IMDG

- EMS F-C, S-V

- Packing Group 2106

- Marine pollutant No

- Special provision 283 371

- Air Carriage � IATA / ICAO

- Packing Instruction 208

- Special Provision A48 A114 A195

15. REGULATIONS

Product contains no ingredients listed in Regulations.

We sells this article in the EU in compliance with the current requirements of REACH.

16. OTHER INFORMATION

The information in this Safety Data Sheet is believed to be, to the best of our knowledge, correct and

complete as of the date issued. However we cannot assume any liability whatsoever for the accuracy

or completeness of the information contained herein.

Final determination of suitability of any product is the sole responsibility of the user. Given the

variety of the factors that can affect a product, some of which are uniquely within the user�s

knowledge and control, it is essential that the user evaluate the product to determine whether it is fit

for a particular purpose.

Winco Easylift BV, Oldenzaal, The Netherlands - Version 12-08-2019